TOPONE ALuminum

TPOE-1605

Non - standard customization

Max diameter: 180 (mm)

Maximum length :500 (mm)

Tolerance: +/-0.005mm

Proofing period : 4-7 days.

Processing cycle: 4-7 days

Annual maximum machining capacity :100000 (parts)

TPOE-1606

Non - standard customization

Max diameter: 180 (mm)

Maximum length :500 (mm)

Tolerance: +/-0.005mm

Proofing period : 4-7 days.

Processing cycle: 4-7 days

Annual maximum machining capacity :100000 (parts)

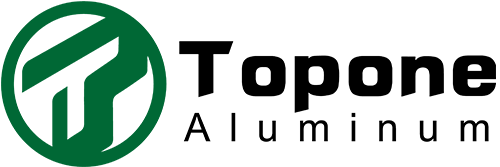

TPDL-1501

Product name: Aluminum Die-Casting LED Shell, Led Heat-Sink

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

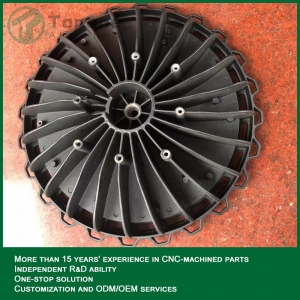

TPDL-1502

Product name: Aluminum Die-Casting LED Shell, Led Heat-Sink

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

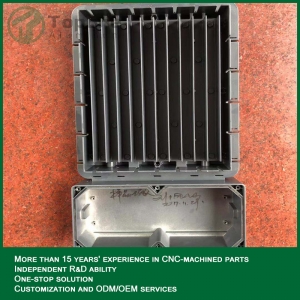

TPIE-1507

Product name: Architectural Aluminum ,Industrial aluminium

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

TPIE-1508

Product name: CNC Lathe Machining SS304 Parts

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

TPIE-1509

Product name: Customized Machined Parts, CNC Machining Anodized Custom SS304 Parts

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

Causes and solutions of sand holes on zinc alloy die casting surface

As we all know, in the process of die casting production, the quality of sand holes on the surface of zinc alloy die casting often occurs. Many simple reasons sometimes affect the consequences of large damage. Topone Metalwork Engineer lists the abnormal analysis of this defect here, for the production personnel of zinc alloy die casting to learn together! Sand hole is a common name for the "hole" defect in die casting, which is mainly manifested in sand hole and slag hole.

One. General sand holes (also called sand holes).

During the whole process of zinc die casting, sand holes on the surface of zinc alloy die casting will be produced due to various reasons. The main characteristics of sand holes are different regularly precipitated sand holes due to different reasons.

The causes of surface sand holes on zinc alloy die castings are as follows:

1. alloy smelting time is too long and thermal insulation is long, causing air absorption and oxidation to intensify.

2. the alloy material is polluted, and at the same time, it causes H2O to enter the burden.

3. cleaning agent is itself wetted into the alloy solution.

4. the recycled material has been seriously corroded, and the surface has changed AL (OH) 3.

5. improper mixing in the smelting process causes more gas to enter the alloy solution.

6. raw materials all gold ingots contain H too much.

Preventive measures should be taken according to the causes mentioned above.

1. Always bake the oven before melting the alloy, thoroughly remove the moisture which can enter the alloy liquid to prevent the increase of (H)

2. all tools contacting the alloy must be bake, the coating agent is evenly coated and dried.

3. the alloy is well protected from rain and damp, preventing AL (OH) 3 from accumulating a large amount of surface area.

4. control the raw materials and strictly control the gas content in the alloy ingots.

5. strictly control all kinds of oil and other pollutants into the alloy, so as to prevent (H) increase.

6. In the degassing process of alloy refining, attention should be paid to the smooth stirring and the moisture-proof of the degassing agent should be stored in order to increase the water-proof vapor.

Two. Immersed sand hole

The following are the reasons for the sand holes on the surface of immersion zinc alloy die casting.

1. mold cavity wall contains volatile substances.

2. There is not completely volatile water on the inner surface of the mold cavity, mold release agent and so on. When the alloy liquid is filled in the die casting, there is no place to evaporate the white gas and immerse the casting.

3. leakage of mold

Preventive measures for surface sand holes of immersion zinc alloy die casting:

1. the use of release agent should be proper and uniform, not excessive and volatile.

2. blow evenly and thoroughly. Do not have any residual liquid on the surface of the cavity.

3. must not allow cooling water to leak into the mold cavity.

Three. Involved sand holes

Defect Characteristics: In the casting, injection and filling process of zinc alloy, gas is involved or contained in the liquid of aluminum alloy. With the filling process, the alloy still has swirl splash and so on. The gas can not be eliminated. As a result, the gas in the alloy solidifies and remains in the casting to form sand holes. The inner wall of the sand holes is smooth and smooth, but not smooth. Clean, there are obvious signs of contamination or corrosion, sometimes even odor, and even, sometimes, can be seen in this hole was rolled up such as oil (punch oil) showing a dispersion distribution.

Method of discovery: appearance inspection or X-RAY after machining.

Analysis of the causes of sand holes on the surface of zinc alloy diecasting

1. improper gating system.

1. gate is too thin.

2. the material tube is too large and the filling rate is too low.

3., the impact is too intense.

4. the gate is not in the right direction.

5. vortex intensified

6. improper opening of exhaust system.

7. exhaust is not smooth.

8. overflow slot is unreasonable.

9. vacuum flow path is not smooth.

2. punch oil consumption is too much, resulting in combustion after pouring alloy, a lot of smoke.

3. filling speed is too fast, resulting in a large number of gas, or too early blockage of exhaust channels.

4. the vacuum system leaks and the vacuum effect is reduced, because the gas in the high-speed filling cavity can not be discharged.

5. machining allowance is too large.

6. deep cavity gas can not be closed.

Preventive measures:

1. change the direction of the metal liquid entering the cavity, preferentially fill the deep cavity part.

2., reduce the injection speed appropriately.

3. when the filling is good, the greater the cross section of the inlet is, the better.

4. The position of the exhaust groove should not be blocked by the alloy liquid flowing into the cavity first, or the overflow groove should be added appropriately. The deep cavity of external vacuum casting can be used mosaic die to facilitate the gas discharge.

5. reduce the amount of punch oil properly to reduce the occurrence of gas in the pipe.

6. increase charging rate.

7. correct use of vacuum device, do not leak.

8. reduce machining allowance.

The above points are Topone Metalwork Die Casting Plant for everyone to analyze the causes of sand holes on the surface of zinc alloy die casting and related solutions, hoping to be of help to the vast number of friends or peers in need. In short, the surface defects of die castings are also one of the common problems in the manufacturing process. In addition to the reasonable design of the die, the quality control in the manufacturing process is also an important link, because it is more appropriate to detect problems early than to fix them later.

These problems should be avoided in electroplating of aluminum alloy die castings

In die casting production, different alloy materials can be manufactured into corresponding blank products by different processes and machines (such as zinc alloy die castings, aluminum alloy die castings, magnesium alloy gold die castings). And then surface processing can become a product that consumers can use. Among them, aluminum alloy die-casting electroplating is a common surface treatment process, but it is more complex than zinc alloy die-casting electroplating process, high requirements, Topone Metalwork today on this issue to talk about the relevant technical points, to avoid unnecessary problems in the process of electroplating.

1. reduce defects in aluminum alloy die castings

Simply put, it is necessary to avoid surface defects (such as surface sand hole, shrinkage, cold lines, corrosion mold, blanking etc.) caused by inappropriate die-casting mold, die-casting environment (cooling system, pressure system, etc.), die-casting machine, manual operation methods and so on in the production process of aluminum die-casting, and further affect the aluminum alloy die-casting. The rate of defective plating increased.

2. avoid surface polishing improper handling defects.

Surface polishing is the primary process for aluminum alloy die casting before electroplating, and it is also very important. Polishing is to remove some defects on the surface of the black embryo casting, and achieve the goal of surface smoothness and smoothness, so as to make the subsequent electroplating easier. However, this process should avoid artificial shortcomings, such as deformation, size changes, quality control should be strict.

3. avoid the incomplete cleaning before plating, resulting in quality problems after plating.

Before electroplating, aluminum alloy die castings need to be cleaned by ultrasonic wave to remove wax and oil so as to achieve surface cleanliness and ensure the reliability of subsequent electroplating. This process should be carried out strictly in accordance with the operation instructions, and the time, temperature and acoustic parameters should be set in accordance with the process requirements.

4. avoid poor adhesion and produce defective products.

The adhesion of alloy products can be detected by a rigorous 100 gram test to know whether the electrodeposits are firm. However, because the surface activity of aluminum alloy is not as high as that of zinc alloy, the adhesion of aluminum alloy die castings after electroplating is not so easy to control. The industry's general solution is to pre-plating before the formal plating, that is, surface passivation and copper substrate, and then formal plating, this scheme has been recognized by the industry.

In a word, in the electroplating process of aluminum alloy die castings, even if the materials of die castings are the same, there will be differences in the process of electroplating because of the different operation methods. In order to ensure the quality of the final surface treated products, it is necessary to calmly analyze and find the appropriate solution to reduce the rate of defect in production.

CNC Lathe Machining

CNC (Computer Numerical Controlled) Machining is a means to remove material using high speed, precision machines that use a wide variety of cutting tools to create the final design. Common CNC machines include vertical milling machines, horizontal milling machines, and lathes. Complex cylindrical shapes can be manufactured more cost effectively using a CNC lathe versus a 3 or 5-axis CNC milling machine. With a CNC lathe, the part stock turns while the cutting tools remain stationary. Conversely, on a CNC mill, the cutting tools move while the stock remains fixed. To create the geometry of a part, the CNC computer controls the rotational speed of the stock as well as the movement and feed rates of the stationary tools. If square features are needed on an otherwise round part, the round geometry is first created on the CNC lathe followed by the square features on a CNC mill. To successfully make a part on a CNC Machine, programs instruct the machine how it should move. The programmed instructions given to the CNC machine are encoded using CAM (computer aided manufacturing) software in conjunction with the CAD (computer aided design) model provided by the customer. The CAD model is loaded into the CAM software and tool paths are created based on the required geometry of the manufactured part. Once the tool paths are determined, the CAM software creates machine code that tells the machine how fast to move, how fast to turn the stock and/or tool, and where to move in a 5-axis X, Y, Z, A and B coordinate system.