TOPONE ALuminum

TPIE-1514

Product name: Aluminum Structural Parts

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

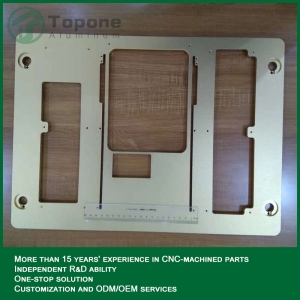

TPIE-1515

Product name: precision-cnc-milling-parts

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

TPOT-1502

Product name: Aluminum Audio power plate

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

TPIE-1516

Product name: Precision-cnc-milled-connecting-shaft

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

TPIE-1517

Product name: CNC milling parts with grey anodizing

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

TPIE-1518

Product name: Machinery Bolt

Quote based on drawing or sample

Customized order is welcome

Material: aluminum, copper, brass, stainless steel, steel, iron, alloy

Finishing: polishing, anodize, sanding powder coating, vacuum plating, silver plating

Machinery equipment: CNC milling, turning machine, general milling, turning machine, grinding machine.

Quality control: inspected by ISO9001:2015

Small orders are accepted

Customized logo: accepted

Changing on material, mold, shape: accepted

Develop on artwork and sketch: accepted

Packing: accepted

Sample: accepted

Rapid entry into the simulation of handling solutions

With this in mind, SCHUNK is putting together an attractive starter kit made up of Mechatronics Concept Designer™ software from Siemens PLM Software, a component library of digital twins from SCHUNK and corresponding support for their use. The tool can be completely integrated into Siemens’ NX™ software. Designers, programmers and project developers can test the simulation software for six months in the full version free of charge. Irrespective of the entry package, licenses of Mechatronics Concept Designer can be purchased from SCHUNK immediately.

“In the future, no one will have to calculate cycle times for periods of several days or spend weeks commissioning handling solutions,” says Chief Executive Officer, CEO, Henrik A. Schunk assuredly. “As part of our digitalization initiative, we have set ourselves the target of allowing systems engineers and integrators to gain entry to the highly efficient world of simultaneous engineering and virtual commissioning as easily as possible.” It is essentially a case of simulating entire assembly systems in three-dimensional spaces and mapping the entire engineering process from the design through to the mechanics, electrics and software right up to virtual commissioning in digitalized form in a single system. “Even experienced designers are amazed at the benefits and the efficiency effects afforded by engineering with Mechatronics Concept Designer,” Henrik A. Schunk reports.

Complete package for simultaneous engineering

“In our opinion, no other simulation software is able to fully cover the systems development process as comprehensively as Siemens’ Mechatronics Concept Designer,” Schunk highlights. From design in the CAD program, simulation, right up to virtual commissioning and real connectivity to the control system, the system covers all phases with minimal media disruptions. While for conventional engineering, mechanics, electrics, and software programming run sequentially one after the other and commissioning doesn’t begin until the end at the assembled automated system, Mechatronics Concept Designer combines all three disciplines in one interface and thereby creates the possibility to have all activities run in parallel. This simultaneous engineering accelerates the entire systems development process, minimizes the complexity, increases the flexibility and ultimately can save a great deal of money. Changes can be applied within no time at all and their feasibility verified. Furthermore, comparable follow-up projects can be implemented a great deal faster than was previously possible.

Mechatronics Concept Designer simulation software from Siemens PLM Software, a component library of digital twins and corresponding support, provides SCHUNK with easy entry into the simulation of handling solutions. Photo: SCHUNK

Everything from a single source

As the simulation software, the component library, the real components and the support all originate from a single source, it is a particularly more time- and cost-efficient entry into simulation software. With this in mind, SCHUNK has created its 24 V mechatronics program for high-performance assembly as digital twins, so that simple assembly systems can also be simulated without comprehensive software expertise. The component library comprises in the first stage the parallel grippers SCHUNK EGP, the linear modules SCHUNK ELP, the rotary gripping modules EGS, and the rotary modules ERS. In the medium term, all gripping system and clamping technology components from SCHUNK will be available as digital twins. The digital twins comprise the CAD volume model with all geometric data for modeling in Siemens’ NX™ software, CAE data (EPLAN), a kinematic behavior model, and a physical model in which the stroke, extension and retraction speed, acceleration, jerk, nominal force, and mass are stored. Added to this are functional components for virtual commissioning to simplify the scenario software and hardware in the loop (SiL/HiL).

Mechatronics Concept Designer simulation software from Siemens PLM Software, a component library of digital twins and corresponding support, provides SCHUNK with easy entry into the simulation of handling solutions. Photo: SCHUNK

Interface for real control

Besides a flow sequence, the software supplies a Gantt diagram in which all phases and dependencies are illustrated. As early as the planning phase, it can be identified where sequential movements are necessary or where parallel movements are possible. By means of automation interfaces, the behavior of the virtual model can be tested on real control systems such as the Siemens’ Simatic S7 or Beckhoff, meaning Plug & Work-capable handling solutions can be implemented. In order to ensure the highest degree of design freedom, component libraries of other manufacturers can already be implemented into the free test phase. Those who want to get further into the software can also make use of training sessions provided by Siemens in addition to the library support provided by SCHUNK.

CNC Lathe Chuck Jaws

Today we will talk about cnc lathe machine jaws. You might read this post as an introductory article about cnc machine jaws. CNC machine jaws are used on a cnc lathe machine to grip the component in cnc lathe machine chuck.

So the sole purpose of the cnc machine jaws is to grip the component in the cnc lathe machine chuck. Therefore almost all the cnc lathe machine jaws have almost same blueprint or you might say that normally all the cnc lathe machine jaws have the same shape and look.

Jaws Selection a CNC Setter Job

Whenever a new component comes into workshop, CNC Setter have to select the jaws to grip that component.

Sometimes cnc setter have those jaws (same cnc machine jaws can be re-used for component grip),but in some situations the component has a shape that is difficult to grip, so cnc setter have to tinker the cnc machine jaws,

sometimes cnc setter have to weld some extra pieces with the standard shape jaws,

and other times cnc setter have to machine the cnc machine jaws itself to make jaws to properly grip the required component.

CNC Machine Jaws Properties

Normally cnc machine jaws has following properties

CNC Machine Jaws Properties

CNC Machine Jaws Properties

CNC Machine Jaws Tee Nuts

CNC Machine Jaws Tee Nuts

Height (s-3)

Width (s-2)

Length (s-1)

Groove width (s-4)

Number of Steps

Serration

Serration Pitch (3P)

Serration Angle (60°)

Hard Jaws

Soft Jaws

Number of Gripping Screw Holes (2 in figure)

Gripping Screw Hole Space (s-7)

Tee-Nuts Size (used to grip the jaw with the chuck)

Gripping Screw (Bolt) Size (used with the Tee-Nuts for grip)

Jaws Face

Jaws Face Shape

Jaws Face Teeth

This cnc machine jaws properties list might be even more longer, but actually I want to tell you that a very simple looking cnc machine jaw is an important entity of the cnc machine workshop and cnc machine jaws has lot more properties than we realize.

Every cnc machine jaw has a height width and length, these sizes are almost dependent on the cnc machine chuck and the component we are going to grip. For bigger cnc machine chucks definitely bigger jaws will suit, because bigger cnc chuck has a slightly wider serration pitch than the smaller cnc machine chucks.

Contact Us

CHINA OFFICE

Address: NO. 211, YongJun Rd, ShuiLang Section, DaLingShan Town, DongGuan City, GuangDong Province 523836, China

Phone: +86-0769 8225 9696

Fax: +86-0769 8225 9797

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Capabilities

30000

322916

Production Staff: 100 to 149

Materials/Components

We mainly use aluminum alloy, stainless steel, carbon steel, brass, copper, pom, acrylic and more as our materials.

We have an advanced precision CNC machine, CNC center machine, auto lathe machine, wire-cutting machine, CNC laser cutting machines, CNC bending machines, CNC punching machines, CNT stamping machine and more.

Advantages

-

Rapid Turnaround

Using the latest CNC machines, Topone produces highly accurate parts in as little as 6 business days.

-

Scalability

CNC Machining is perfect for production of 1-10,000 parts.

-

Precision

Offers high-precision tolerances ranging from +/-0.001″ – 0.005″, depending on customer specs.

-

Material Selection

Choose from over 50 metal and plastic materials. CNC Machining offers a wide variety of certified materials.

-

Custom Finishes

Select from a variety of finishes on solid metal parts, built to precise design specifications.